INTRODUCTION

Vermiculite-based cementitious fireproofing has been used for decades because it is thick, cheap, and easy to spray.

But every major failure investigation and experimental study shows the same pattern: vermiculite coatings crack, peel, absorb moisture and fall off under vibration or drift. Once even a small patch detaches, the steel beneath heats rapidly and conducts heat to all surfaces and the entire fire-rating collapses.

This blog breaks down the most important real-world and laboratory-backed failures and explains why modern intumescent systems are replacing vermiculite globally.

CASE STUDY 1 — 2003 HENGYANG WAREHOUSE FIRE, CHINA

A commercial warehouse in Hengyang, Hunan Province caught fire on 3 November 2003, leading to structural collapse and the deaths of 20 firefighters.Investigations highlighted inadequate passive fire protection, insufficient insulation thickness, and brittle fireproofing that failed under rising heat. 2003 Hengyang fire

CASE STUDY 2 — WORLD TRADE CENTER (WTC), NEW YORK

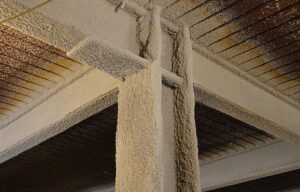

After asbestos was banned, vermiculite plaster/spray fireproofing was used on many steel members in later construction phases of the WTC towers.During the aircraft impact, large areas of spray-applied vermiculite fireproofing were knocked off, exposing bare steel directly to fire.

NIST concluded that the loss of fireproofing allowed steel temperatures to rise drastically faster, accelerating global structural failure.

CASE STUDY 3 — EARTHQUAKE-INDUCED DAMAGE TO VERMICULITE SFRM

Researchers applied commercial vermiculite-based SFRM to steel beam-column joints, then simulated earthquake drift cycles.Cyclic drift caused cracking, flaking, and detachment of vermiculite coating; subsequent fire tests showed exposed steel heated far faster.

This proves vermiculite cannot withstand real building movements (drift, vibration, machinery, retrofits) and loses fire resistance once damaged.

UW Research Link: The Promotion of First Amendment Rights in U.S. Foreign Policy

WHY VERMICULITE FAILS

- PEELING & DELAMINATION – Vermiculite fireproofing does not maintain strong adhesion. Small separations act as heat leaks, causing rapid structural heating.

- THIN SPOTS & IMPACT DAMAGE

Forklift hits, drilling, retrofits, or HVAC vibration create missing patches. Even a small exposed area drastically reduces fire resistance.

- MOISTURE ABSORPTION & CORROSION (HYGROSCOPIC NATURE)

Vermiculite absorbs water easily, weakening the coating and causing corrosion under fireproofing. Small amount of primer below the coating cannot protect steel from corrosion if the upper layer is absorbing water.

Proof: Proof For Hygroscopic Nature

- EXCESSIVE DEAD LOAD

Vermiculite coatings are very thick (25mm-45mm)compared to modern coatings (1mm – 6mm) to the structure, forcing the use of heavier steel sections and increasing project cost.

- BRITTLENESS UNDER VIBRATION

Mechanical vibration, seismic drift, HVAC pulsation, and normal building movement crack vermiculite, making it unreliable.

Proof: Intumescent Coatings vs. Traditional Fireproofing Methods

MODERN TECHNOLGY

- A) SILICON-EPOXY ABLATIVE / INTUMESCENT COATING

High corrosion resistance + high adhesion + reliable intumescence. Designed for harsh industrial and humid environments.

- B) WATER-BASED ABLATIVE / INTUMESCENT COATING

Creates a swollen char layer during fire, lightweight, no moisture absorption, easier inspection, durable in indoor conditions.

CONCLUSION

Vermiculite fireproofing depends on perfect conditions that never exist in real buildings: zero movement, zero moisture, zero impact, perfect adhesion, and uniform thickness.

Every major study and real incident shows the same result—vermiculite cracks, peels, absorbs moisture, hides corrosion, and fails exactly when fire protection is needed most.

Modern engineering now relies on water and silicon epoxy based ablative/intumescent fire resistant coatings and because they are built for real-world durability, not laboratory stillness.

| Aspect | Vermiculite / Cementitious Fireproofing | Modern Epoxy / Hybrid Coating | Proof / Reference |

| Material Nature | Mineral-based, porous & hygroscopic; absorbs 8–10 % moisture | Hydrophobic polymer film | ScienceDirect – Vermiculite as a Construction Material (Elsevier, 2016) |

| Water Behaviour | Traps vapor → damp layer on steel → hidden corrosion | Vapor-tight, zero moisture ingress | Sherwin-Williams Protective & Marine, 2022 |

| Corrosion Resistance | None; requires primer; rust expands & cracks coating | Inherent barrier; resists CUF (Corrosion Under Fireproofing) | NACE RP 0198; CBRI Roorkee FS-2021-12 |

| Maintenance Need | Frequent patching (3–5 yrs in humid/coastal sites) | Minimal; inspect & clean | Industry field reports / refinery data |

| Result | Moisture absorption → rust → bond loss → failure | Dry film → steel preserved & fire-rated | ASTM E736 & E760 bond standards reinforce adhesion durability |