Introduction – The Hidden Risk in Modern Buildings

On 21st January 2021, a massive fire broke out at the Serum Institute of India’s Pune campus, the world’s largest vaccine manufacturer. The incident took place in a building that was still under construction, not in the main Covishield production unit, but it still caused five deaths and heavy infrastructure loss.

The blaze spread quickly through multiple floors, fueled by construction material and the absence of proper fire containment. Fire tenders reached the site promptly, but by then, large parts of the building were already engulfed.

This incident is not just a tragic accident. It is a textbook example of how neglecting passive fire protection (PFP) at the design and construction stage creates vulnerabilities that no active firefighting system can fully control.

How the Fire Started and Spread

The blaze at Serum Institute’s Pune campus began in a building under construction, triggered by welding sparks and accelerated by the absence of passive fire protection (PFP).

– Initial Ignition (Welding Work): Sparks from welding on the top floor ignited plastic sheets, insulation boards, and packaging. Without fire-retardant coatings or flame-proof boards, these materials burned instantly, becoming the fire’s fuel.

– Rapid Vertical Spread (Ducts & Shafts): The flames quickly spread through open ducts, shafts, and unsealed penetrations. Without fire-resistant duct coatings and firestop barriers, these pathways acted like chimneys, channeling flames and toxic smoke across floors.

– Structural Weakness (Steel): Heat built rapidly, and unprotected steel beams began losing strength once the temperature crossed 500°C. Without intumescent or ablative fire-resistant coatings, the steel structure offered no time buffer, leading to faster collapse and loss of integrity.

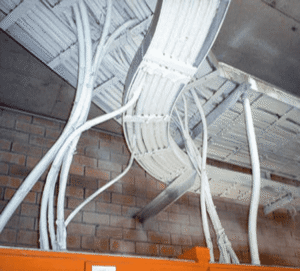

– Toxic Smoke and Entrapment (Cables & Plastics): Burning plastics, cables, and construction materials released dense, poisonous smoke. Without fire-retardant cable coatings, the insulation burned freely, producing lethal fumes that trapped workers on upper floors.

– Delayed Containment (Sprinklers Alone Couldn’t Help): Active systems like sprinklers and alarms were incomplete and ineffective in stopping spread. Without compartmentalization using firestop mortars, sealants, and insulation wool, the fire jumped sections unchecked, overwhelming firefighters upon arrival.

Negligence of Consultants & Builders

The Serum Institute fire was not an unavoidable tragedy — it was the outcome of avoidable design and execution failures. The consultants and builders overlooked basic principles of passive fire safety at multiple levels:

– Dependence on Sprinklers and Alarms: Active systems were treated as the only line of defense. By the time they engaged, the fire had already spread unchecked.

– Unsealed Ducts and Shafts: Vertical openings and service shafts were left exposed, turning them into direct channels for smoke and flames.

– No Compartmentalization: Cable and pipe penetrations lacked proper sealing, allowing fire to jump from one section of the building to another without resistance.

– Exposed Structural Steel: Steel members had no thermal protection, causing them to weaken rapidly once temperatures rose beyond 500°C.

– Unprotected Cables: Electrical wiring burned freely, releasing thick toxic smoke that led to fatalities.

These were not oversights but systemic failures — the outcome of prioritizing cost and speed over safety. In reality, each of these vulnerabilities had well-established solutions under Indian and international fire codes, but they were ignored.

How Easy It Was to Save It

The tragedy at the Serum Institute campus was not inevitable. At every stage, proven passive fire protection measures could have stopped the fire from escalating:

– Ignition Stage: Flammable construction materials ignited instantly during welding. With flame-retardant treatments and proper housekeeping, sparks would not have turned into a blaze.

– Ducts & Shafts: Vertical shafts acted as chimneys, carrying fire and smoke across floors. With fire-resistant duct coatings and linings, the fire would have been contained at its source.

– Openings & Penetrations: Gaps around pipes, cables, and joints created pathways for spread. With firestop mortars, sealants, and insulation barriers, fire and smoke would have been compartmentalized.

– Structural Steel: The steel frame began weakening within minutes of exposure. With fire-resistant coatings on steel members, the structure would have held its strength for hours, giving time for evacuation and firefighting.

– Cables & Wiring: Burning insulation released thick, toxic smoke that trapped workers. With fire-retardant cable protection, ignition would have been slowed, and smoke reduced.

Every failure point had a straightforward, available solution. The tools existed, the standards existed — but they were not applied. This is what turned a controllable incident into a deadly fire.

The Lesson – Passive Fire Protection is Non-Negotiable

The Serum Institute fire shows a truth that repeats itself in almost every major blaze: sprinklers, alarms, and fire brigades react after the fire has already spread. By then, lives and assets are already at risk.

Passive fire protection works differently. It is built into the structure itself — silent, invisible, and always active. It stops fire at its point of origin, buys precious evacuation time, and ensures buildings remain standing long enough for people to survive and firefighters to act.

What happened in Pune was not because solutions were unavailable, but because they were not applied. Fire safety cannot be treated as an afterthought or a cost-cutting option. Every duct, cable, joint, and steel column must be treated as a potential weak link unless protected.

The lesson is clear: neglecting passive fire protection is not just negligence — it is a design choice that decides whether people live or die when a fire breaks out.

At Ameetuff

For over 35 years, Ameetuff Technical Paints has been safeguarding India’s critical infrastructure through advanced fire-resistant and fire-retardant coating systems. From structural steel, ducts, and cables to barrier sealants and tunnel protection, our solutions are tested and approved by CSIR-CBRI and Government of India laboratories.

We are proud members of NFPA, NACE, and ICC, and our systems have protected projects of national importance — including the New Parliament Building, Central Vista, major airports, refineries, naval bases, and metros.

Buildings may rise on concrete and steel, but they stand safe only on fire protection. That’s the foundation Ameetuff delivers.