INTRODUCTION

Fires don’t always start big — but in a building with gaps in its fire safety measures, they don’t stay small for long.

Comprehensive fire safety relies on two layers of defence: active systems such as sprinklers, alarms, and suppression equipment, and passive systems such as fire-resistant coatings, barriers, and compartmentation. When either layer is missing or poorly maintained, vulnerabilities multiply.

Bare structural steel, untreated ducts, uncoated cables, and combustible materials can turn a minor ignition into a multi-floor incident within minutes — even in buildings with functional sprinklers. Heat, flames, and smoke can travel through ducts, cable trays, joints, and façade elements, compromising escape routes and structural stability.

This article examines how fires can start, how they spread through different building systems, and where effective fire safety measures — active and passive — can stop them.

How Fires Begin: Common Triggers and Real Incidents

Fires rarely start as large-scale disasters. Most begin with small, everyday faults or oversights — but without proper safety measures, they can escalate within minutes.

– Electrical Fault in Cable Trays – Overloaded cables can ignite and carry flames between floors. Geetanjali Tower, India (2025): Short circuit in unsealed ducts forced evacuation of 400 residents.

– Kitchen Fires – Grease or appliance flare-ups can spread via unprotected ducts. Kitchens cause ~18% of fire deaths globally (2024).

– Construction/Storage Hazards – Combustible materials in unfinished areas ignite fast. Guangzhou Jianye Building, China: Fire climbed 30 floors without any fire systems.

– Small Ignitions Near Combustibles – Candles, cigarettes, or heaters can trigger major fires. Harrow Court, UK: Candle fire spread rapidly due to poor compartmentation, killing 3.

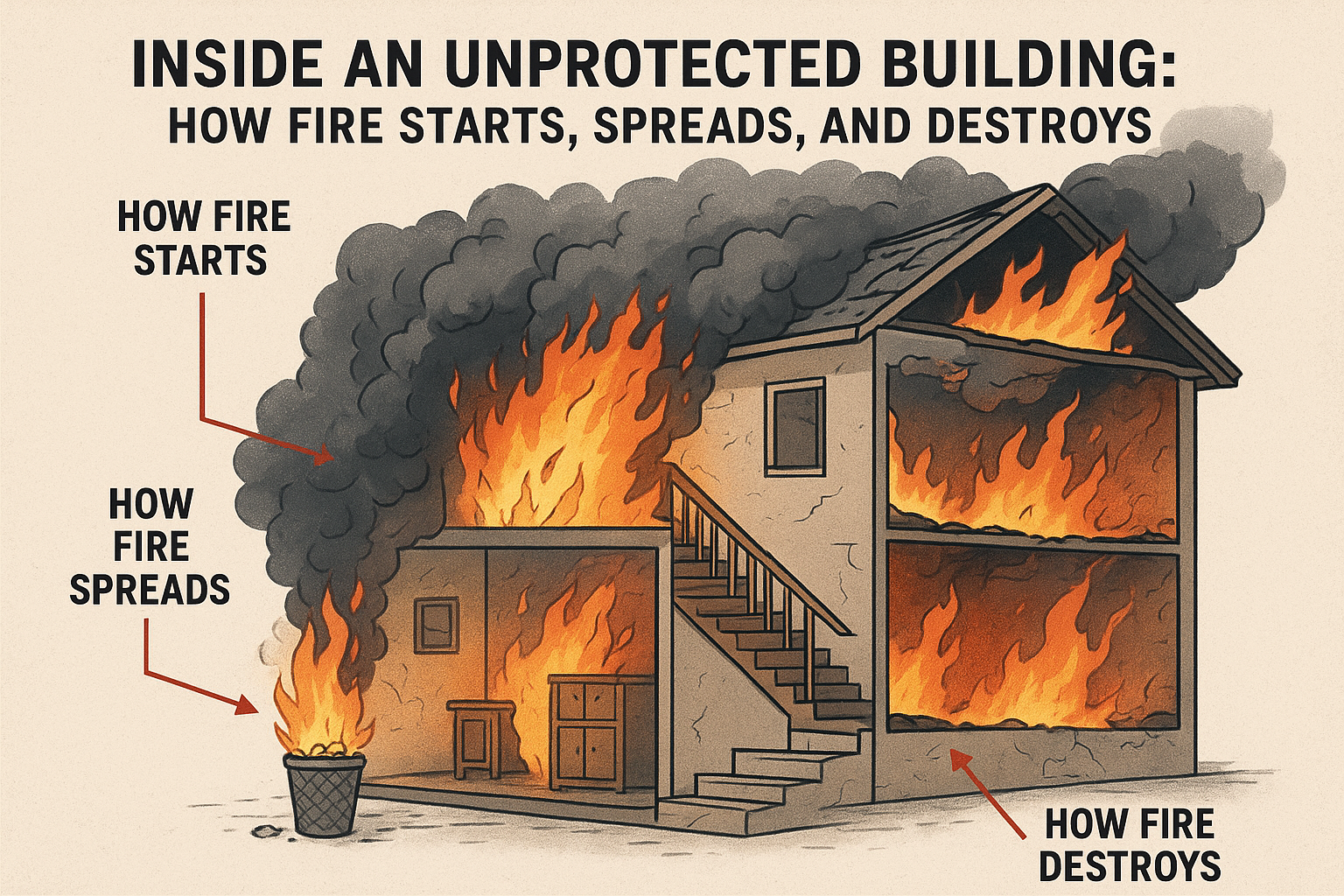

How Fire Spreads in an Unprotected Building

Once ignition occurs, the speed and direction of fire spread depend on the building’s design, materials, and safety measures. In an unprotected structure, the pathways are wide open.

– Through Ducts and Shafts – HVAC ducts, service shafts, and cable risers act as highways for flames, heat, and smoke. Without internal fireproofing or compartmentation, a localized fire can reach multiple floors in minutes.

– Across Structural Steel – Uncoated steel rapidly loses strength above 500°C. Heat transfer can cause structural failure long before flames are visible on every floor.

– Along Electrical Cables – Bundled, unprotected cables can burn like a fuse, spreading fire and smoke between critical zones such as control rooms and data centers.

– Via Combustible Surfaces – Untreated wood, fabric, or composite panels feed flames and accelerate surface spread, especially along corridors and façades.

– Through Gaps and Penetrations – Openings around pipes, ducts, and joints allow flames and toxic smoke to bypass barriers entirely.

Even a fast sprinkler response may only slow visible flames — hidden fire and heat continue to travel through concealed spaces, creating secondary ignition points far from the source.

Stopping Fire in Its Tracks: Key Intervention Points

In every fire, there are critical points where spread can be stopped — if the right protection is in place. When these points are left exposed, fire moves unhindered, turning a contained incident into a building-wide disaster.

1. Ducts & Vertical Shafts

HVAC ducts, electrical risers, and service shafts can act as open conduits for flames and smoke. Applying fire-resistant duct linings and sealing shafts with tested barriers ensures that fire stays confined to its origin zone, preventing rapid multi-floor spread.

2. Structural Steel

Steel loses up to 50% of its strength at around 550°C. Without insulation, this can happen within minutes of exposure. Fire-resistant coatings slow heat transfer, keeping load-bearing members stable for up to 4 hours — long enough for evacuation and firefighting intervention.

3. Cables & Electrical Infrastructure

Unprotected cables burn quickly and emit toxic smoke, with flames travelling along their length like a fuse. Fire-retardant cable coatings maintain circuit integrity during fires, preventing shutdown of alarms, emergency lighting, and communication systems when they’re most needed.

4. Combustible Interior Materials

Untreated wood, fabric, and composite panels are fast-burning fuel sources. Applying fire-retardant treatments delays ignition and slows flame spread, reducing both temperature rise and smoke generation in escape routes.

5. Openings & Service Penetrations

Any gap around pipes, ducts, or joints is a potential bypass for fire and smoke. Fire stop barriers and sealants close these routes, cutting off concealed spread and maintaining the compartmentation needed for safe evacuation.

When combined with active fire safety systems such as sprinklers and alarms, these measures create a layered defence. If one element underperforms — due to mechanical failure, human error, or delayed response — the others stand ready to contain the threat.

Disaster vs. Contained Outcome

To understand the difference fire safety measures make, compare these two timelines from the same ignition scenario — an electrical short in a cable tray inside a high-rise commercial building.

Without Comprehensive Fire Safety:

00:00 – Ignition: A spark ignites cable insulation. Flames travel along the tray toward the service shaft.

00:03 – Vertical Spread: Unsealed shaft allows smoke and heat to rise three floors within minutes.

00:07 – Secondary Ignition: Flames reach unprotected cables in another zone, knocking out emergency lighting.

00:10 – Structural Threat: Heat conducts to uncoated steel beams nearby, beginning loss of structural strength.

00:15 – Full Evacuation Crisis: Multiple escape routes are compromised by smoke; fire continues to spread unchecked.

With Integrated Fire Safety Measures:

00:00 – Ignition: Spark ignites cable insulation.

00:01 – Containment: Fire-retardant coating limits flame spread along the tray.

00:03 – Vertical Barrier: Fire-stopped shaft prevents upward smoke and flame movement.

00:06 – Structural Stability Maintained: Fire-resistant coating on steel absorbs heat, preventing early deformation.

00:10 – Controlled Incident: Fire is limited to the origin zone, active suppression systems extinguish remaining flames, and evacuation proceeds in clear, smoke-free corridors.

Ameetuff fire safety

Every major fire teaches the same lesson: prevention and containment are far more effective than reaction alone. While alarms, sprinklers, and suppression systems are critical, they can only do so much if a building’s physical pathways for fire and smoke remain unprotected.

Ameetuff provides a complete passive fire protection suite designed to work alongside active systems, creating a multi-layered defence. Our solutions cover:

– Structural steel fire-resistant coatings – Maintain stability for up to 4 hours.

– Duct fire-resistant coatings – Stop fire and smoke from travelling through HVAC systems.

– Cable fire-retardant coatings – Reduce flame spread and toxic smoke, protect circuit integrity.

– Wood and fabric fire-retardant treatments – Delay ignition and slow burn rates.

– Fire stop barrier systems – Seal gaps, penetrations, and joints to block hidden spread.

All products are tested and approved by CSIR-CBRI & Government of India laboratories, meeting BS 476 and other international standards. Backed by over 35 years of expertise, Ameetuff’s solutions have been trusted in high-risk projects such as the New Parliament Building, PMO, Seabird Naval Base, metro systems, airports, and tunnels.

Fire safety is not a single product — it’s a complete system. With Ameetuff, that system is designed, tested, and proven to hold the line when it matters most.